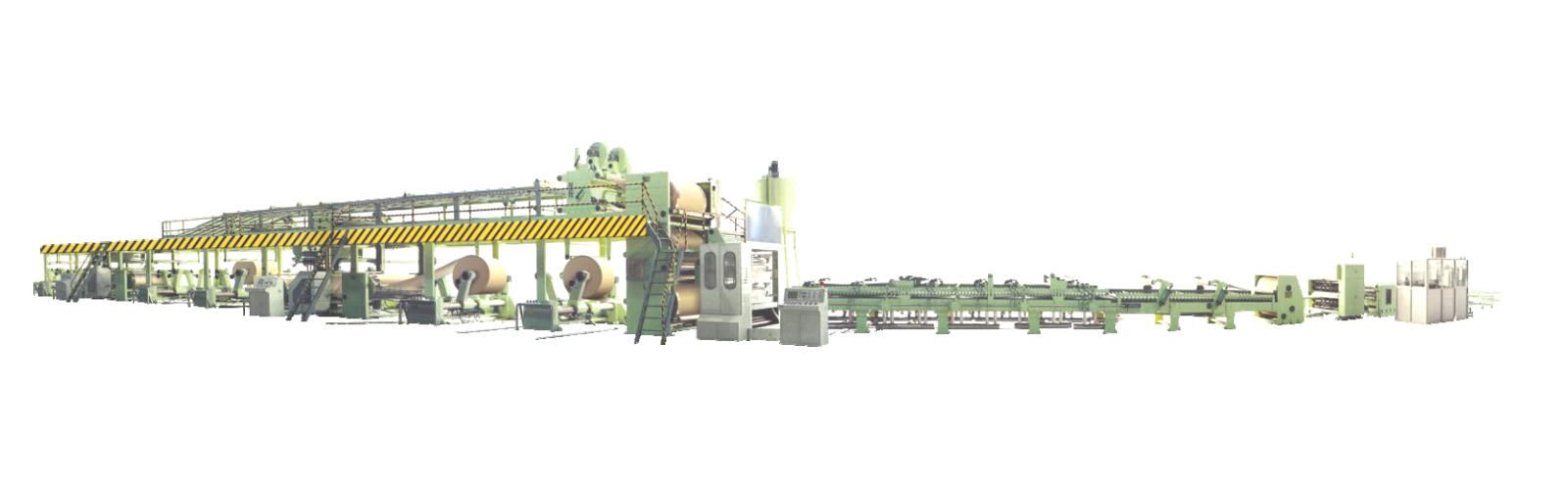

The Corrugated Paper production line is comprised of the following parts: raw paper stand, heating tunned sin^e fecer corrugatJng machine, crane, multiphase pre-heater, folder ^ue machine, dual surface h的ting and forming machine, line pressing paper dividing machine, traverse cutler, stacking machine and boiler. The raw paper stand, passing throu^i the heating tunnel, vAiere th« paperls heated and the moisture Inside the paper 1$ adjusted Then the paper Is sent Into the sln^e facer corrugating device and Is corrugated and shape-formed, adhered to another paper, forming single facer corrugated paper. After that, by the crane the paper Is sent to pre-heated byihe multi-phase pre-heater. The ^ue putting madilne puts glue onto the paper, and the glued paper is sent to the dual smiace heating and forming machine, at this moment the final corrugated paper is formed and outputted contiiiuausly.

The formed paper then pass through the cutting and folding machine, wrtiere the paper Is longitudinally cut and press-fbldedL and traverse cut, finally formed rectan^B corrugated papers can be produced complete. At the end, corrugated paper Is stacked, assorted, and counted by the staddng machine, and you wfU see the final products outputted by this \^iole line continuously.